Is Dye Sublimation the Best Branding Method for Your Mug Artwork?

Dye Sublimation printing has become a popular printing technique on a range of items, from lanyards, through umbrellas, to mugs. This article describes the process and explains the benefits of using this technique, together with its limitations.

The Process

Dye Sublimation - or Dye Sub for short - involves transfer paper with your design, a specially coated mug and a heat press. The sublimation ink is unique: upon applying heat and pressure it changes from a solid state directly into gas - without transforming into a liquid. This allows it to bind into the mug coating, at the same time preserving all the intricacies of the artwork. We print the ink onto transfer paper that is later applied onto the mug. The polyester coating on the mug is required to take the ink - it is impossible to print Dye Sub on a mug without it. Polyester lanyards and umbrellas don't require the coating as the polyester they are made of will take the printing. Once the transfer paper is attached to the mug, we place it in a special heat press, like the one in the image. The transfer of the ink onto the mug is initiated by heat and controlled with pressure and time. When it is complete, the mug is placed in water to cool and settle.

An example of a machine used to print dye sublimation mugs

An example of a machine used to print dye sublimation mugs

The Benefits

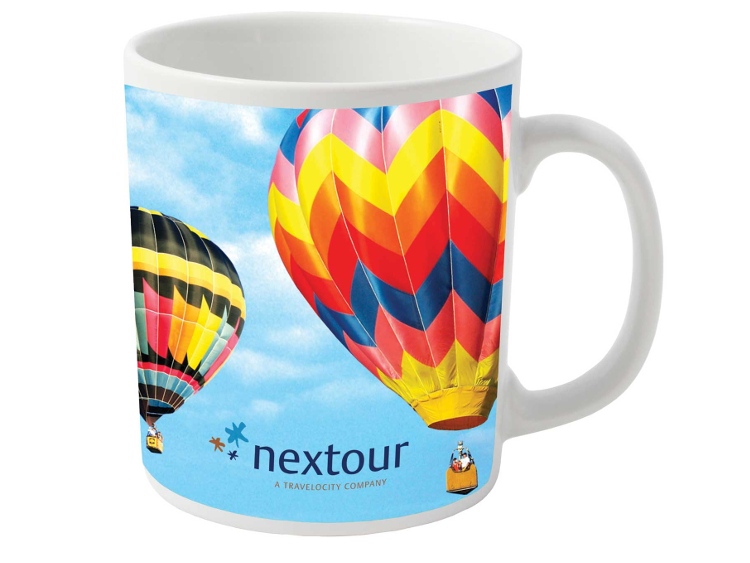

With our top quality printers, Dye Sublimation produces stunning results in terms of design and colour reproduction. It is perfect for photos and complex artwork. We offer great prices and lead time! Dye Sub is an easy, quick and cheap process. We can print and deliver these mugs in as few as two working days from artwork approval (delivery in UK mainland). The price also usually works out cheaper than full colour transfer print or multi-colour screen print - our other popular mug branding methods. Your artwork will be printed top-to-bottom, handle-to-handle, allowing for maximum exposure and great branding. It is even possible to not leave any space at all round the bottom and the rim of the mug - the information about this is included on the relevant mugs pages on the corporate site.

These mugs' vibrant designs have been achieved using dye-sublimation printing

These mugs' vibrant designs have been achieved using dye-sublimation printing

The Limitations

Dye Sub is great for full colour printing but if your design consists of a few block colours, I'd recommend screen printing - it can be more cost effective and the printing is more durable. We can also better match corporate pantone colours. We don't recommend washing Dye Sublimation mugs in a dishwasher because the harsh cycles may cause the colours to fade and the design to get damaged. We can, however, apply special extra coating to make these mugs dishwasher safe. We tested these mugs to withstand 1,000 washes. This is not a standard option and is only possible on a few shapes at the moment - ask for details if you require dishwasher safe Dye Sublimation mugs. Because of the need to use the heat press, we can't Dye Sub print on all shapes. Curved walls prevent the use of the heat press. On straight-walled mugs, we can only brand on the outside. Dye Sublimation printing is not possible on the bottom, handle, or inside of the mug. For this, you need to opt for transfer print.

Browse Dye Sublimation Mugs >>

The Choice

We now use Dye Sublimation for most full colour mug branding but if you are unsure if this is the way to go, send us your artwork. We will assess it free of charge to advise the most effective printing method for you.

Talk to Us

»

01204 577 995

info@UKCorporateGifts.co.uk